Your cart is currently empty!

INTRODUCING … STEVE DALE

We have design consultants working with clients on projects all over the world, but regardless of where a piece of furniture will eventually travel – it will have been made at home in our UK workshop.

We took time out with our Workshop Manager – Steve Dale to learn about how he and his team deliver the craftsmanship and quality that have earned our Internationally renowned reputation for the very best in British manufacturing.

INTRODUCE YOURSELF?

I’m the Workshop Manager, I’m responsible for making sure that every piece of furniture is made to the highest quality and despatched to the client on time.

I manage over 50 craftspeople whom vary in skills and specialisms. Getting all these skill sets to work in harmony to produce our high-quality pieces is a big task, but I wouldn’t have it any other way.

WHAT’S YOUR STORY?

I’ve been working with wood as man and boy. I started working in the industry around the age of fourteen. Every school holiday I would go along with my Dad to work in the local Kitchen Manufacturers. At sixteen I started to operate machines and by the time I had turned twenty-one I’d finished my apprenticeship in wood machining. Determined to learn more, I moved into the fitting and assembly and by twenty-six years old I’d become the Foreman. I spent six years as a foreman then took the opportunity to join Clive Christian Furniture Co. and I’ve never looked back.

I’ve have been with Clive Christian Furniture Co. for twenty-two years now. I began my journey as a CNC machine operator. I spent two years in that role before being promoted to machine shop charge hand. I then worked in the offices checking cutting lists before being promoted to Assistant Workshop Manager and my current role Workshop Manager in 2016.

WHAT’S A TYPICAL DAY?

A typical day flies by. From when the workshop opens at 7.00am – aside from an hour I allow to respond to emails and queries you will usually find me with the teams in the workshop.

I like to make time to be with and listen to the team’s opinions. Be it the precision machine operations, joinery, marquetry or assembly – each project is different, so we are always reviewing how we approach manufacturing techniques. I also spend time each day with the Technical office and design team to ensure a joined-up approach to each aspect of the projects we are working on.

WHAT IS THE MOST CHALLENGING ASPECT OF YOUR JOB?

It’s recruitment and it’s a concern for many skilled industries. The craftsmanship skills of our joiners, Wood Machinists and Veneers is hard to come by in the younger generation. Colleges in the area no longer run courses for the skill remit that we require- so to ensure we keep these age-old techniques sustainable we are introducing apprenticeships in the company.

HOW LONG DOES IT TAKE FROM SOMEONE TO BECOME A ‘TIME HONOURED’ CRAFTSMAN OR MACHINIST?

Back when I did my City and Guilds course, many years ago, it was a five-year course and even now I find myself learning new ways to manufacture. So, I would say with new trends and techniques it is a continuous cycle of learning. Unfortunately, there aren’t enough courses for young people to learn a trade, in the workshop we tend to train most of our people in house by shadowing our best craftsmen.

WHAT’S YOUR FAVOURITE MACHINE…?

Ha! It’s a company joke that I can talk passionately about machines for hours – and I can!

Whilst we use a lot of hand-crafted techniques – our specialist machines are key to the precision areas of our business – everyone wants their furniture to fit! I would have to say my favourite is the SCM Record for the CNC with 12 tool changer. This machine gives us the flexibility to machine more intricate designs in the timber. I’ve got my eye on a 5 axis CNC. If we got one of those, we would have the capability to manufacture and machine furniture parts on 5 surfaces.

WHATS IS THE MOST REWARDING ASPECT OF YOUR JOB?

I love to see the finished projects. I have been fortunate enough to see our furniture fitted in many client’s homes. I always feel an immense sense of pride knowing those specific pieces have been made by us.

WHAT HAS BEEN YOUR PROUDEST MOMENT?

Being asked to escort HRH The Princess Royal on a tour around the workshop. To say I was nervous would be a massive understatement. I have shown numerous clients, suppliers and media around but this was momentous. She was a very lovely lady, genuinely interested in the team and what we do – and she knew her stuff!

Second to that, being made Workshop Manager was a proud moment. After 22 years of working at Clive Christian Furniture Co. it proves hard work and dedication pays off.

DO YOU HAVE A FAVOURITE PIECE?

I honestly couldn’t pick an individual piece or project, as there are so many. We’ve done all kinds of projects which I’ve enjoyed such as Fire surrounds, Mayfair mantles, Regency glass doors to tricky curved units. I would have to say yes to all! I have an immense sense of pride for everything we make.

DOWNTIME?

For the past 6 years I have been Chair of the Governors for the local school, I aim to pop in the school at least once a week and if I have time have lunch with children.

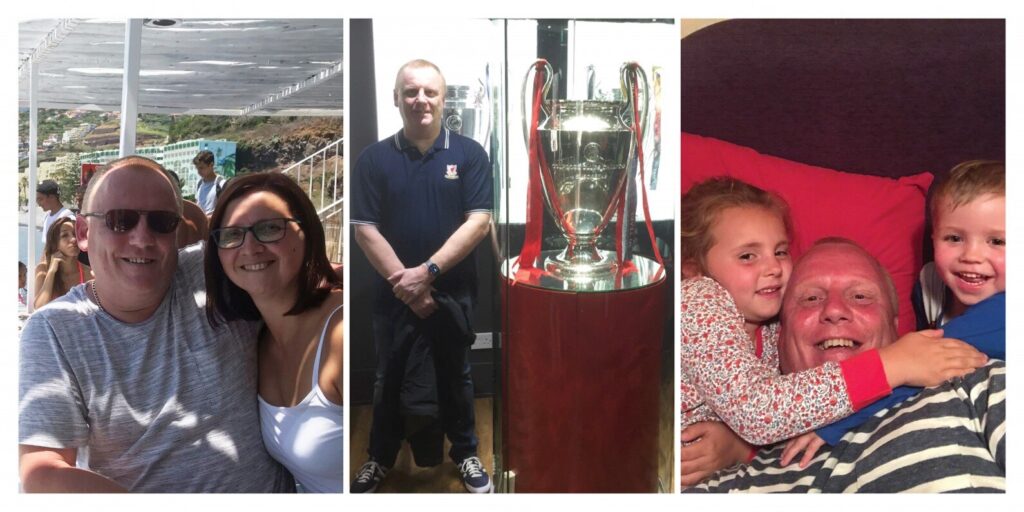

I love spending time with my family, I have been happily married to my lovely wife Alison for 26 years, people say she deserves a medal for putting up with me (Personally I’m not sure what they are on about). I have 3 children whom I am immensely proud of and 2 Grandchildren who are my absolute world. Oh! And a little puggle called Leo, whose an absolute pain but we love him. I’ve recently bought a Boa constrictor and can’t really explain why as I’ve been told it grows up to 12 feet long!

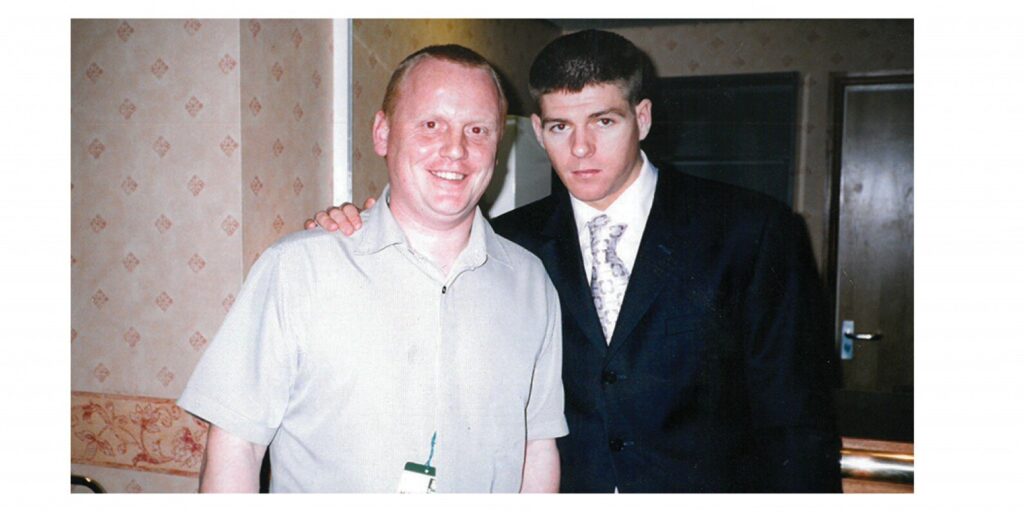

My second love would have to be Liverpool F.C. We’ve had our many ups and downs over the past 44 years but you’ll always find me cheering on The Reds! It was a pleasure to install some furniture into one of my favourite players home.

IN ANOTHER LIFE?

Easy a footballer! When I was younger, I’d often dream about scoring the winning goal against Manchester United in the FA cup final (or any final for that matter), I still have that dream now but I don’t think my legs could take it.